In high-risk environments, whether in military zones, disaster-prone areas, or industrial facilities dealing with hazardous substances, keeping people safe requires rapid response and precise control over protective shelters. This is where the Shelter Control System (SCS) plays an indispensable role. Acting as the nerve center for shelter operations, the SCS ensures that protective measures are deployed quickly, efficiently, and without human error during emergencies.

This article dives into how the Shelter Control System works, explores its key components, and explains why it is essential for safety and operational efficiency.

What Is the Shelter Control System (SCS)?

The Shelter Control System is an integrated network designed to manage and monitor protective shelters during emergencies such as chemical leaks, biological threats, nuclear fallout, or severe weather events. It automates critical processes—ventilation control, air filtration, power management, communication systems—so occupants remain safe from external threats while maintaining essential living conditions inside.

For organizations dealing with NBC (nuclear, biological, chemical) risks, an SCS is not just an option but a necessity. It allows instant switching between normal and protective operations, ensuring that protective barriers like sealed doors, airlocks, and filtration systems activate within seconds.

Core Functions of the Shelter Control System

The efficiency of a shelter relies heavily on how quickly it can adapt to changing threat levels. The SCS makes this possible through several primary functions:

- Automatic Threat Detection

The system works hand-in-hand with sensors for radiation, chemical contamination, and biological hazards. When readings reach danger thresholds, the SCS initiates protective measures without waiting for human intervention. - Air Filtration & Ventilation Management

One of the most critical aspects in a shelter is clean, breathable air. The SCS controls air filters and Positive Pressure Ventilation setups, ensuring outside contaminants cannot enter. It can switch between recirculation mode and full filtration mode depending on the situation. - Environmental Control

The system regulates temperature, humidity, and lighting to keep the shelter habitable for extended periods. - Power Supply Management

In emergencies, power sources can be unstable. The SCS manages backup generators and battery systems to ensure the continuous operation of all critical shelter functions. - Communications Hub

Integrated communication systems within the SCS keep occupants informed and connected to external command centers, enabling coordinated responses.

Safety Features That Make It Reliable

Safety in a shelter isn’t only about being sealed off—it’s about ensuring that operations inside remain stable, predictable, and error-free. The Shelter Control System achieves this through:

- Fail-Safe Mechanisms

Redundant systems ensure that if one part fails, another automatically takes over. - Manual Override

While automation is vital, human operators can override functions if necessary. - Continuous Monitoring

The system keeps track of all vital parameters, sending alerts if anything drifts outside safe limits.

These features together reduce risks caused by technical malfunctions or human error.

Efficiency Benefits Beyond Safety

While the most obvious advantage of an SCS is protection during emergencies, it also offers efficiency benefits during normal operations:

- Reduced Human Workload

Automation means fewer personnel are needed for round-the-clock monitoring. - Faster Switching Between Modes

The transition from standard operation to full protective mode happens in seconds, reducing exposure risks. - Optimized Resource Use

The system fine-tunes airflow, energy usage, and equipment operation based on occupancy levels and environmental conditions, lowering operational costs over time.

These efficiencies mean organizations can maintain readiness without incurring excessive operating expenses.

Real-World Applications

Shelter Control Systems are in use across various sectors:

- Military Bases – To protect soldiers from NBC attacks or environmental hazards.

- Industrial Facilities – Such as chemical plants or nuclear power stations, where leaks could endanger workers.

- Disaster Shelters – In regions prone to hurricanes, tornadoes, or floods.

- Research Labs – Especially those working with infectious diseases or hazardous materials.

In all these settings, the SCS provides not only safety but also peace of mind, knowing that the shelter environment is under constant, intelligent control.

How the Shelter Control System Ensures Long-Term Reliability?

For a system that must work flawlessly during an emergency, regular maintenance and testing are critical. Most shelter facilities using an SCS conduct routine diagnostics to ensure sensors are calibrated, filters are functioning, and backups are ready.

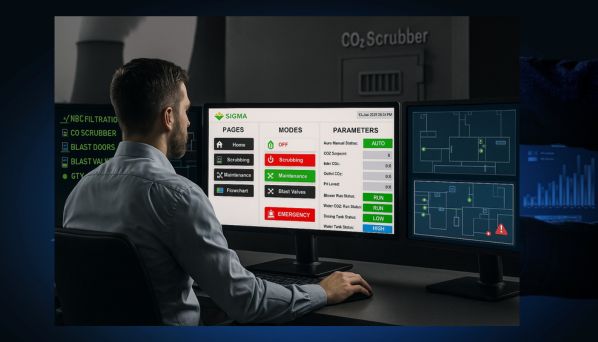

Additionally, modern SCS setups integrate with digital monitoring dashboards, enabling remote supervision and predictive maintenance. This helps identify potential issues before they become problems.

Looking Ahead: Technological Advancements

Advancements in sensor technology, AI-enhanced threat detection, and improved filtration materials are making the Shelter Control System even more efficient. While the core idea remains the same—protecting lives—new designs emphasize faster processing, better integration with security networks, and enhanced user interfaces for operators.

Future SCS installations might incorporate machine learning algorithms that predict threat likelihoods based on weather patterns, industrial activity, or geopolitical conditions. This proactive approach would allow facilities to prepare in advance, further reducing response time.

Conclusion

A robust Shelter Control System is much more than a set of automated doors and filters—it is a finely tuned protective network designed to safeguard occupants from life-threatening hazards. By combining automation, real-time monitoring, and efficient resource management, it ensures shelters remain safe, functional, and cost-effective.

For any facility where the consequences of an environmental, industrial, or NBC hazard could be severe, investing in a well-designed SCS is one of the smartest safety measures available today. It not only guards against worst-case scenarios but also elevates operational efficiency every single day.