Thread machining is a fundamental process in construction and building, ensuring that components fit together securely, transfer loads effectively, and maintain structural integrity. From heavy-duty fasteners in steel beams to plumbing connections and machinery assembly, precision threading is what allows projects to stay reliable over time. Understanding the methods, equipment, and practical uses of thread machining can help construction professionals select the right approach for efficiency and long-term performance.

What Is Thread Machining?

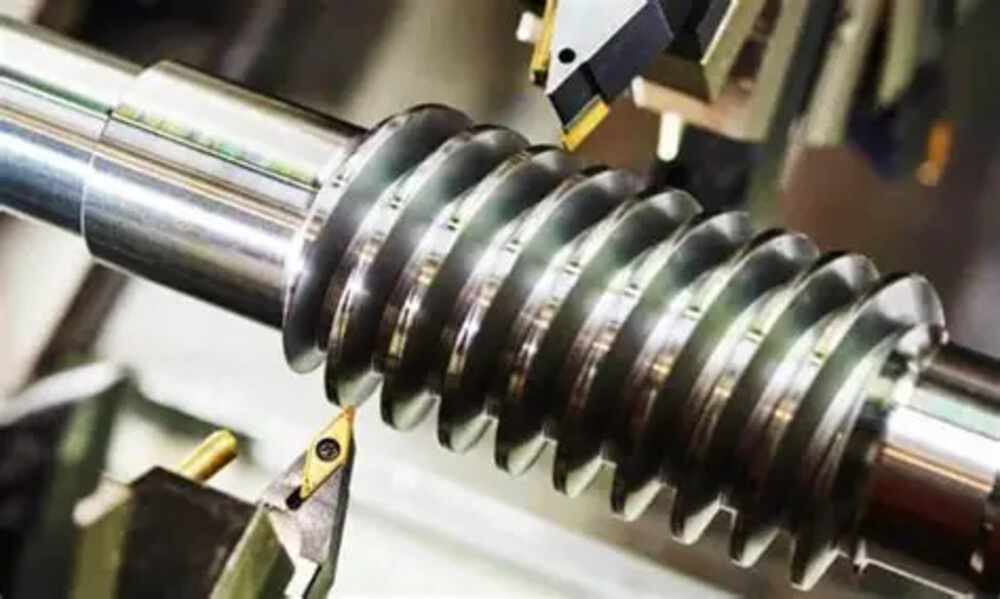

Thread machining is the process of cutting helical grooves (threads) into a workpiece so it can function as a screw, bolt, or nut. Unlike rolling or forming, which shape threads by displacement, thread machining removes material directly to achieve a precise geometry. This makes it particularly valuable when working with hard materials, large diameters, or custom designs where high accuracy is required.

In construction, reliable threading ensures that structural joints, fixtures, and mechanical assemblies hold together under stress. Whether building high-rises, bridges, or installing heavy machinery, thread machining provides the accuracy and consistency that standardized fasteners alone may not cover.

Methods of Thread Machining

1. Thread Turning

Thread turning is performed on a lathe. A cutting tool traces the helical path along the rotating workpiece. This method is highly versatile and ideal for external threads on shafts or pipes. It’s commonly used for large-diameter components in steel frameworks or piping systems where threading dies may not be practical.

Advantages:

- Suitable for both internal and external threads.

- Works well on tough materials like stainless steel.

- Precise control over pitch and depth.

2. Thread Milling

Thread milling uses a rotating cutting tool on a machining center or CNC mill. The tool follows a spiral toolpath to cut threads, either internally or externally. It’s especially effective for producing threads in difficult-to-machine materials or when multiple thread sizes must be cut with one tool.

Advantages:

- High accuracy and excellent surface finish.

- Can cut left- or right-hand threads easily.

- Lower risk of tool breakage compared to taps.

3. Tapping

Tapping is the most common method for creating internal threads. A tap is driven into a pre-drilled hole, cutting threads as it advances. In construction, taps are widely used for threading holes in metal plates, brackets, and equipment housings.

Advantages:

- Fast and economical for smaller threads.

- Easy to use with handheld tools or automated machines.

- Standardized taps available for common thread profiles.

4. Thread Grinding

Thread grinding is reserved for applications requiring exceptional precision, such as high-load bolts or specialty machinery components. A grinding wheel profiles the thread with extreme accuracy, ensuring exact fit and finish.

Advantages:

Achieves the tightest tolerances.

Superior surface quality.

Essential for critical applications in infrastructure and heavy equipment.

Equipment for Thread Machining

Construction-focused workshops and on-site operations rely on a range of equipment depending on scale and precision requirements:

- Engine Lathes and CNC Lathes – Best for thread turning on large structural components or custom fittings.

- CNC Machining Centers – Enable thread milling with accuracy and repeatability for complex projects.

- Tapping Machines – Streamline mass production of threaded holes in steel plates and equipment housings.

- Handheld Taps and Dies – Practical for on-site adjustments, repairs, or threading in tight spaces.

- Thread Grinders – Specialized equipment used in manufacturing high-precision parts for cranes, lifts, and other load-bearing systems.

Uses of Thread Machining in Construction

Thread machining underpins countless applications across the construction industry. Key uses include:

- Structural Connections – Bolts and threaded rods secure beams, columns, and trusses in steel-frame buildings.

- Plumbing and Piping – Threads ensure leak-proof joints in pipes carrying water, gas, or chemicals.

- Heavy Equipment Assembly – Excavators, cranes, and lifts rely on precision-threaded fasteners for durability.

- Concrete Formwork – Threaded tie rods and anchor bolts hold formwork in place during pouring.

- Custom Fabrication – Non-standard thread sizes are often required for retrofits or unique architectural designs.

Choosing the Right Method

For construction professionals, the right thread machining method depends on project scale, material, and performance needs:

- Use tapping for fast, cost-effective internal threads in smaller components.

- Choose turning for external threads on large shafts and pipes.

- Opt for milling when flexibility and precision are required across different sizes.

- Rely on grinding for mission-critical, high-load components.

Selecting the proper equipment and process not only saves time but also ensures that joints remain reliable under demanding construction environments.

Final Thoughts

Thread machining is far more than a workshop detail—it’s the backbone of strong, safe, and lasting construction. With methods ranging from tapping to grinding and equipment designed for both shop and site use, professionals can match the process to the project’s exact demands. By investing in the right threading solutions, construction teams gain precision, durability, and confidence that every fastener and connection will hold up under pressure.

Article by: https://tokohasil.com