The Additive Manufacturing Market size was valued at USD 27.45 Billion in 2024 and the total Additive Manufacturing revenue is expected to grow at a CAGR of 21.86% from 2025 to 2032, reaching nearly USD 133.51 Billion.

𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞 𝐋𝐚𝐧𝐝𝐬𝐜𝐚𝐩𝐞

The additive manufacturing (AM) market is characterized by a dynamic and competitive landscape, with key players continually innovating to maintain their positions. Stratasys, 3D Systems, and Desktop Metal are prominent leaders, offering a range of 3D printing solutions across various industries. Stratasys, for instance, provides comprehensive polymer-based AM systems, catering to sectors like aerospace, automotive, and healthcare. 3D Systems offers diverse technologies, including metal and plastic 3D printing, serving industries such as automotive, aerospace, and healthcare. Desktop Metal focuses on metal 3D printing solutions, emphasizing speed and cost-effectiveness for mass production. These companies are engaged in strategic initiatives, including mergers and acquisitions, to enhance their technological capabilities and market reach. For example, in September 2024, Nano Dimension acquired Markforged, aiming to integrate its expertise in metal and composite 3D printing with Nano Dimension’s advanced electronics printing technologies, thereby strengthening its position in the AM market.

Emerging players are also making significant strides in the AM market by introducing innovative technologies and business models. Companies like Relativity Space and Alloyed are leveraging advanced 3D printing techniques to disrupt traditional manufacturing processes. Relativity Space utilizes the world’s largest metal 3D printer, “Stargate,” to print entire rocket components, aiming to revolutionize aerospace manufacturing. Alloyed, on the other hand, focuses on producing high-performance metal components for industries such as aerospace, automotive, and defense, utilizing its proprietary digital design software and additive manufacturing capabilities . These companies are capitalizing on the growing demand for customized and complex parts, offering solutions that traditional manufacturing methods struggle to achieve. Their innovative approaches are challenging established players and contributing to the rapid evolution of the AM market

Get a sample of the report: https://www.maximizemarketresearch.com/request-sample/146140/

Additive Manufacturing: Defining the Future of Production

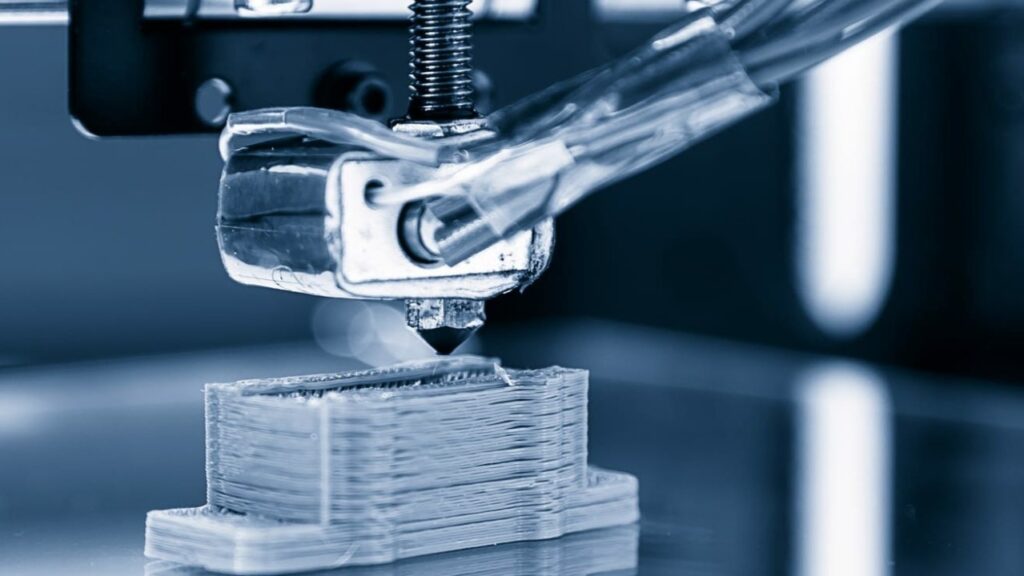

Additive manufacturing (AM) refers to a suite of advanced technologies that build three-dimensional objects layer by layer from digital models, contrasting with traditional subtractive manufacturing methods that involve cutting, drilling, or milling materials away. These technologies encompass a range of processes, including stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), direct metal laser sintering (DMLS), electron beam melting (EBM), and binder jetting, among others.

AM has disrupted conventional production paradigms by offering unparalleled design freedom, reduced material waste, rapid prototyping capabilities, and the ability to manufacture complex geometries that were previously impossible or prohibitively expensive.

Market Growth Drivers

The additive manufacturing market’s explosive growth is underpinned by multiple converging factors:

- Rising Adoption in Aerospace and Automotive Sectors

Aerospace and automotive manufacturers increasingly utilize AM for producing lightweight, high-strength components that improve fuel efficiency and reduce emissions. The ability to create intricate parts with fewer assemblies accelerates production timelines and lowers costs. For instance, aircraft manufacturers are printing engine components, brackets, and interior parts, while automakers use AM for rapid prototyping and low-volume custom parts.

- Medical and Dental Applications Surge

The healthcare sector is rapidly embracing additive manufacturing for producing patient-specific implants, prosthetics, surgical guides, and dental crowns. Customization, biocompatibility, and reduced lead times make AM ideal for personalized medicine. The demand for bio-printing, including tissue and organ fabrication, is also fostering market expansion.

- Technological Advancements and Material Innovation

Continuous improvements in printing speed, accuracy, and multi-material printing capabilities are making AM more accessible and cost-effective. The development of new materials — from advanced polymers to metal alloys and ceramics — is broadening the scope of applications, enabling manufacturers to meet stringent industry standards.

- Supply Chain Optimization and On-Demand Manufacturing

The COVID-19 pandemic highlighted vulnerabilities in global supply chains, prompting industries to adopt additive manufacturing for decentralized and flexible production. AM allows companies to produce spare parts and components locally and on-demand, reducing inventory costs and lead times.

- Sustainability and Waste Reduction

Environmental concerns and stringent regulations drive the adoption of AM due to its ability to minimize raw material usage and lower carbon footprints compared to traditional manufacturing processes. The additive approach reduces scrap rates and supports circular economy initiatives.

Get a sample of the report: https://www.maximizemarketresearch.com/request-sample/146140/

Market Segmentation

The global additive manufacturing market is segmented to provide a granular understanding of demand dynamics:

By Technology:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Binder Jetting

- Material Jetting

- Others

Each technology offers unique benefits, suited to specific applications and materials, influencing market share and growth rates.

By Material:

- Polymers

- Metals

- Ceramics

- Composites

Polymer-based additive manufacturing currently dominates the market due to cost-efficiency and versatility, but metal AM is rapidly growing, especially in aerospace and medical fields.

By Application:

- Automotive

- Aerospace & Defense

- Healthcare

- Industrial Manufacturing

- Consumer Goods

- Education & Research

- Others

Automotive and aerospace lead adoption due to the critical need for lightweight and customized parts, while healthcare’s personalized medicine continues to fuel growth.

By End-User:

- Original Equipment Manufacturers (OEMs)

- Service Providers

- Research Institutes & Academia

OEMs are increasingly integrating AM into their manufacturing workflows, while service providers offer access to AM technology without high capital investment.

By Geography:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

North America and Europe currently hold significant market shares, driven by established industrial bases and R&D activities, whereas Asia Pacific is the fastest-growing region due to expanding manufacturing infrastructure and government initiatives.

Get a sample of the report: https://www.maximizemarketresearch.com/request-sample/146140/

Challenges and Restraints

Despite its promising outlook, the additive manufacturing market faces several hurdles:

- High Initial Capital Expenditure: The cost of advanced AM equipment and materials remains a barrier, particularly for small and medium enterprises (SMEs).

- Material Limitations: While expanding, the range of materials suitable for AM still lags behind traditional manufacturing, limiting some applications.

- Process Standardization: Lack of universal quality standards and certification processes hinders broader adoption in regulated industries like aerospace and medical.

- Skilled Workforce Shortage: Operating and maintaining AM systems require specialized skills, leading to talent gaps.

- Production Speed: While suitable for prototyping and low-volume production, AM is often slower than mass manufacturing methods, restricting use cases.

Key Market Players

The additive manufacturing market is highly competitive and fragmented, with major players investing heavily in innovation, strategic partnerships, and geographic expansion. Leading companies include:

- 3D Systems Corporation

- Stratasys Ltd.

- EOS GmbH

- HP Inc.

- SLM Solutions Group AG

- Renishaw plc

- Desktop Metal, Inc.

- Materialise NV

- ExOne Company

- GE Additive

These players focus on developing advanced machines, proprietary materials, and integrated software platforms to offer end-to-end AM solutions.

Emerging Trends Shaping the Market

- Integration of AI and IoT

The fusion of artificial intelligence (AI), machine learning, and Internet of Things (IoT) with AM is enabling real-time monitoring, predictive maintenance, and improved quality control, significantly enhancing production efficiency.

- Multi-Material and Hybrid Printing

Technologies enabling simultaneous printing of multiple materials, including conductive and insulating components, are opening new applications in electronics, wearables, and smart devices.

- Metal Additive Manufacturing Expansion

Metal AM’s rising adoption in producing critical load-bearing parts for aerospace, automotive, and healthcare is a major trend, backed by ongoing research in alloys and process optimization.

- Bio-Printing and Regenerative Medicine

Bioprinting is evolving beyond research labs, with growing investments in fabricating tissues, cartilage, and even organs, promising revolutionary changes in transplantation and drug development.

- Sustainable AM Practices

Companies are exploring recycled materials, bio-based polymers, and energy-efficient printers to align AM with global sustainability goals.

Regional Outlook

- North America remains a leader due to strong aerospace and defense sectors, significant R&D funding, and early adoption of new technologies.

- Europe is driven by automotive manufacturing, healthcare innovation, and government support for Industry 4.0 initiatives.

- Asia Pacific is the fastest-growing market, fueled by expanding manufacturing bases, rising infrastructure investments, and growing AM startups, especially in China, Japan, and India.

- Latin America and Middle East & Africa present emerging opportunities, supported by industrial modernization efforts and increasing awareness of AM benefits.

Future Market Outlook

The additive manufacturing market is expected to witness continuous growth, reaching a valuation exceeding tens of billions of dollars by 2031. Industry experts predict that advancements in materials science, automation, and digital manufacturing will drive adoption from prototyping to full-scale production.

In the coming decade, AM will become integral to smart factories and digital supply chains, supporting mass customization, rapid innovation cycles, and resilient production networks

Explore More Related Reports:

India Metal Fabrication Equipment Market Trends

Global Industrial Heaters Market Share

About Maximize Market Research:

Maximize Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Maximize Market Research:

3rd Floor, Navale IT Park, Phase 2

Pune Bangalore Highway, Narhe,

Pune, Maharashtra 411041, India

sales@maximizemarketresearch.com

+91 96071 95908, +91 9607365656